Fluid Flow

Durcor PTFE lined pipe provides a low friction smooth bore that will maintain its characteristics for many years. Although smooth when purchased new, over time metallic piping will scale, pit, and be a growth surface for fungi, adhesives, reaction crystals, calcium, etc. The PTFE surface of Durcor piping is not prone to any of these and will thus maintain a predictable low level of pressure drop and prevent the pump from working harder.

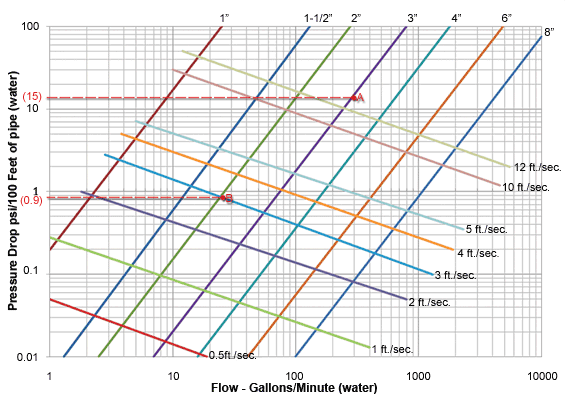

Using the following chart, the expected pressure drop per 100 feet of Durcor pipe as well as expected loss in feet of head for common fittings can be determined.

| Equivalent Feet of Head Loss Through Fittings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Values are in feet of pipe. | ||||||||||

| Size (in) |

Elbows | Standard Tees | ||||||||

| 90° | 45° | Thru Run | Thru Branch | |||||||

| 1 | 1.8 | 0.9 | 1.2 | 4.5 | ||||||

| 1-1/2 | 3.5 | 1.8 | 2.3 | 7.5 | ||||||

| 2 | 4.5 | 2.3 | 3 | 10 | ||||||

| 3 | 7 | 4 | 4.1 | 15 | ||||||

| 4 | 10 | 6 | 6 | 20 | ||||||

| 6 | 15 | 9.5 | 10 | 32 | ||||||

| 8 | 19 | 12 | 14 | 42 | ||||||

Pressure drop can be determined from head loss by applying the following formula:

Example:

3” Durcor pipe carrying a fluid flow rate of 300 GPM. To determine the predicted loss in pressure over 100 feet of pipe, follow the 3” line (purple) in the chart to the 300 GPM horizontal axis location, which is (2) vertical lines to the right of the 100 GPM line. Where the 3” line intersects the 300 GPM line, (A), draw a straight horizontal line to the left vertical axis. It will land at 15 psi.

Example:

2” Durcor pipe carrying a fluid travelling at 3 ft/sec. Follow where the 2” line (green) and the 3 ft/sec line (turquoise) intersect one another (B). Draw a straight horizontal line to the left vertical axis to 0.9 psi.

Durcor

Durcor